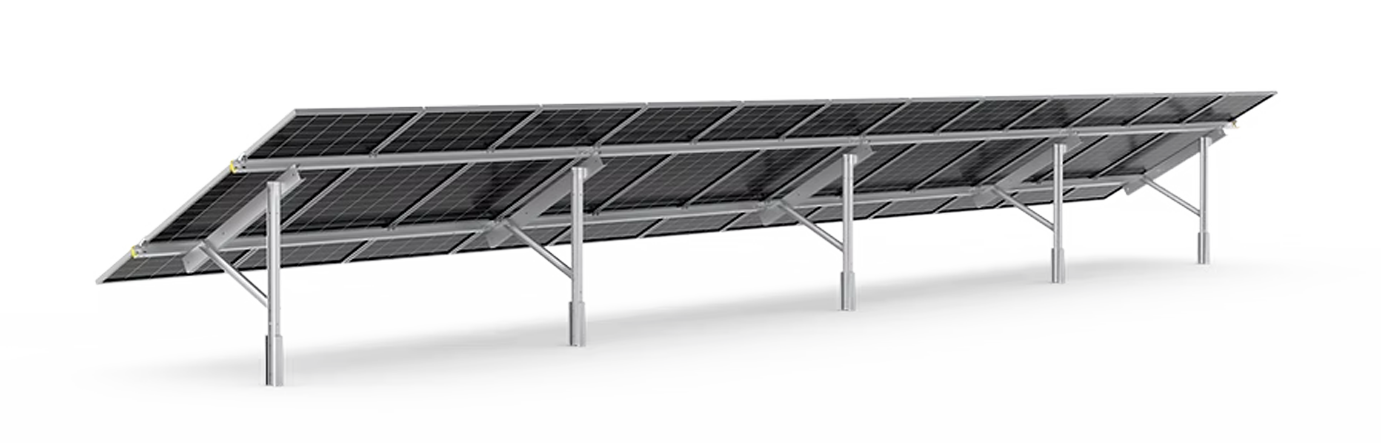

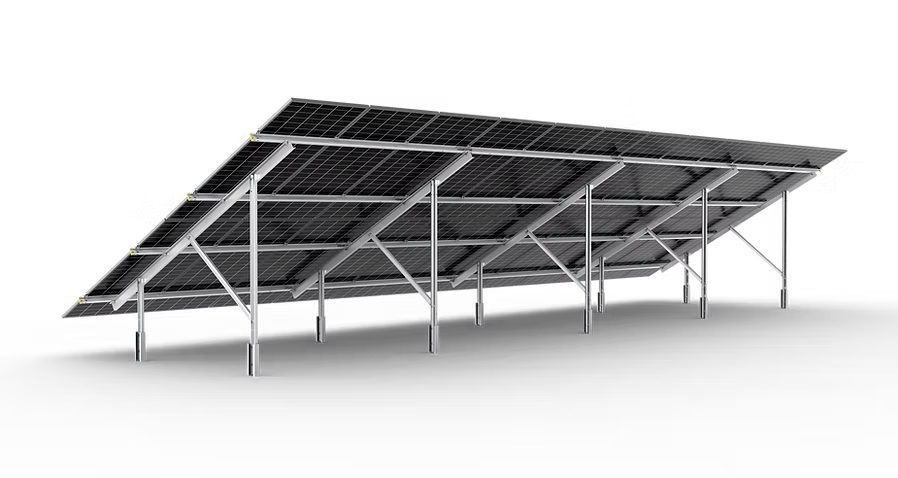

Mounting Systems - 1-in-portrait

The 1-in portrait system maximises limited space with a lower profile, ideal for height-restricted areas. Its streamlined, vertical arrangement enhances aesthetics and efficiency on narrow plots, reducing installation costs with its simpler configuration.

-

Modular is held in stock for rapid distribution and can utilise 8 different foundation options, ensuring that almost no terrain is off limits. The modular design allows for the tables to be built in bays of 2 or 3 panels wide and is suitable for ground up to a maximum slope of approximately 5°.

Panel configuration:

1-in-Portrait

Panel min and max length:

Minimum length: 1650 mm. Maximum length: 2470 mm, Minimum length: 1650 mm. Maximum length: 2470 mm

Purlin configuration:

1-in-portrait: 2 purlins, position determined by panel dimensions and clamping zones

Panel clamping zones:

Please refer to the panel manufacturer’s specification

Panel clamp specifications:

Panels fitted using aluminium top hat and end clamps, with sliding clamps to give mounting positions

System angles:

20°, 25°, 30°

System min and max heights:

20°:

Single post: Min: 831mm, Max: 1419mm

Twin post: Min: 676mm, Max: 1261mm

25°:

Single post: Min: 848mm, Max: 1544mm

Twin post: Min: 672mm, Max: 1369mm

30°:

Single post: Min: 862mm, Max: 1661mm

Twin post: Min: 664mm, Max: 1460mmBay sizes:

2-panel and 3-panel wide

Table configuration min and max:

1 panels x 2 panels min. 30 panels x 1 panels max.

Bay pitches:

2000mm, 2500mm, 3000mm, 3500mm. Each pitch can have 100mm added if an Extension Joiner is used

Foundation types:

Single Post: C Pile, V Pile, Concreted Pile,

Twin Post: Ballasted, X Anchor, Ground Anchor, Direct Fix, Screw Pile

Material specification:

S450 grade steel. Coating ZM310 & ZM800

Wind speed:

Fundamental basic UK wind velocity within the UK up to 26m/s

Snow loads:

0.7 kN/m² max

Design codes:

Designed in accordance with BS EN 1991-1-4:2005 + A1:2010.BS EN 1090 & BS EN 1991 Parts 1, 3 & 7

Description text goes here

-

Whatever the terrain or ground conditions, our range of foundation options have been designed to work on even the most challenging of sites. Our aim is to make sure that, when using a Solarport system, there is no site that's off-limits. We will work with you to ensure the correct foundations are paired to your system and site location, maximising site viability and yield.

Driven pile

The most commonly used foundation, the driven pile, can be used for most projects. The pile profile and length will be specifically designed to increase efficiency and strength for the foundation.

Anchored

With the use of only hand tools, our patented 'X-Anchor' allows for solar installation on reclaimed ground such as former landfill, or any site that needs shallow embedment and/or no heavy machinery.

Ballasted

No breaking ground with our ballast system; allowing for a vast amount of applications. Options include the use of high density concrete blocks, railway sleepers and pre-cast concrete mono-block.

Screw Pile

This foundation provides a fast and efficient installation method for ground with a high clay content. Its durability and adaptability make it an ideal solution for a broad range of small to medium-sized projects.

-

Streamlined Design and Installation

Modular is renowned for its intelligent design that streamlines the entire process from site planning to deployment, making it a preferred choice for those seeking efficient solar mounting solutions. By reducing component variations and employing universal parts, Modular not only speeds up the installation process but also ensures easy system expansion with a single fixing size used throughout.

Compatibility and Flexibility

Engineered to be versatile, Modular supports a wide array of solar panel sizes and is compatible with almost any terrain, making it a flexible option for a variety of solar ground mount projects. Whether you’re dealing with commercial or residential settings, Modular integrates seamlessly with any of our foundation options, optimising each installation to specific site conditions.

Cost-Effective & Risk-Reducing Features

The Modular mounting system is designed to reduce errors and maximise productivity, cutting down on the time and resources needed on-site. These features help decrease labour costs and enhance overall efficiency. Safety is also a priority, with Modular’s design minimising common installation risks and promoting safer work environments.

Flexible Panel Configuration

Modular is available in multiple configurations, such as 1-in-Portrait and 2-in-Portrait, with three tilt angle options to enhance solar capture. Each mounting system complies with international quality standards and is adaptable to various ground conditions, making Modular a comprehensive solution for your solar energy needs.

Diverse Foundation Options

Our broad selection of foundation options ensures that Modular systems can be installed on virtually any terrain. From ground anchors in challenging conditions to ballasted systems where minimal ground disturbance is necessary, Modular provides stable and durable foundations for every solar project.

Similar products

Images

Let’s Chat

Interested in our products or working with DeCarb Solar? Fill out some info and we will be in touch shortly! .